Simpson and Hancock`s Practical Operations Management Chapter

advertisement

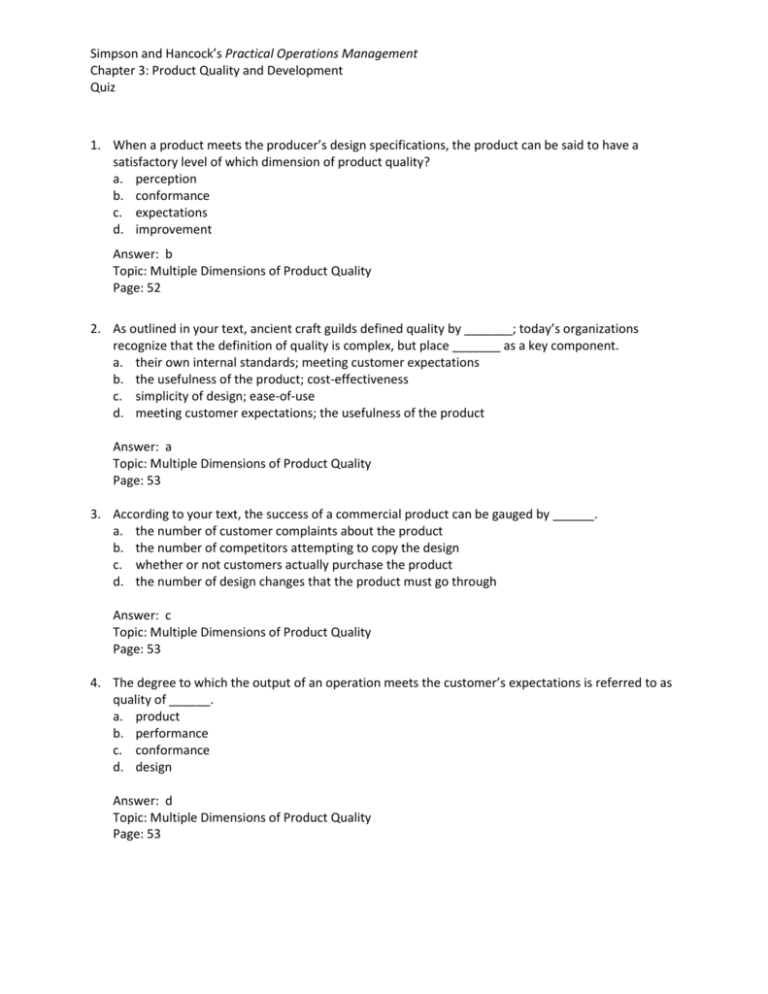

Simpson and Hancock’s Practical Operations Management Chapter 3: Product Quality and Development Quiz 1. When a product meets the producer’s design specifications, the product can be said to have a satisfactory level of which dimension of product quality? a. perception b. conformance c. expectations d. improvement Answer: b Topic: Multiple Dimensions of Product Quality Page: 52 2. As outlined in your text, ancient craft guilds defined quality by _______; today’s organizations recognize that the definition of quality is complex, but place _______ as a key component. a. their own internal standards; meeting customer expectations b. the usefulness of the product; cost-effectiveness c. simplicity of design; ease-of-use d. meeting customer expectations; the usefulness of the product Answer: a Topic: Multiple Dimensions of Product Quality Page: 53 3. According to your text, the success of a commercial product can be gauged by ______. a. the number of customer complaints about the product b. the number of competitors attempting to copy the design c. whether or not customers actually purchase the product d. the number of design changes that the product must go through Answer: c Topic: Multiple Dimensions of Product Quality Page: 53 4. The degree to which the output of an operation meets the customer’s expectations is referred to as quality of ______. a. product b. performance c. conformance d. design Answer: d Topic: Multiple Dimensions of Product Quality Page: 53 Simpson and Hancock’s Practical Operations Management Chapter 3: Product Quality and Development Quiz 5. Quality of conformance requires a product to conform to the producer’s specifications, and in doing so, guarantees a product’s success. True or False? Answer: False Topic: Multiple Dimensions of Product Quality Page 54 6. The simultaneous and continuous pursuit of improvement in both the quality of design and conformance through the involvement of the entire organization is referred to as ______. a. operations management b. total quality management c. quality of conformance d. quality function deployment analysis Answer: b Topic: Total Quality Management Page: 55 7. Which of the following is NOT a distinguishing feature of modern product quality management? a. voice of the customer b. employee involvement c. continuous improvement d. product adaptation Answer: d Topic: Total Quality Management Page: 55 8. Leonard is the production manager at a food processing plant. Part of his job is to ensure that all food used by the plant in the manufacturing of its products is of the highest quality. As such, Leonard has the authority to refuse any shipment from a supplier that he feels is below his company’s standards. This is an example of ______. a. employee empowerment b. voice of the customer c. continuous improvement d. a Pareto analysis Answer: a Topic: Total Quality Management Page: 56 9. A company is experiencing continual delays in the shipment of its products to its customers. A Pareto analysis reveals that there are eight factors causing the delays, but of these eight, there are three factors that account for the majority of the delays. According to Vifredo Pareto, these three factors would be referred to as ______. Simpson and Hancock’s Practical Operations Management Chapter 3: Product Quality and Development Quiz a. b. c. d. the deciding factors the critical few the vital variables the essential elements Answer: b Topic: Total Quality Management Page: 57 10. Which of the following correlation coefficient scores indicates the strongest degree of linear relationship? a. r = .20 b. r = .80 c. r = 0 d. r = -.10 Answer: b Topic: Total Quality Management Page: 58 11. A fishbone diagram is also called a cause-and-effect diagram. True or False? Answer: True Topic: Total Quality Management Page: 61 12. The purpose of a control chart is to detect ______. a. the “critical few” b. correlation coefficients c. assignable variations d. regular patterns Answer: c Topic: Total Quality Management Pages: 63-64 13. Which certification of quality management was first developed by Motorola in the 1980s and is currently used in organizations around the world? a. DMAIC b. ISO 9000 c. Statistical Process Control d. Six Sigma Answer: d Topic: Total Quality Management Page: 64 Simpson and Hancock’s Practical Operations Management Chapter 3: Product Quality and Development Quiz 14. Which of the following accurately defines the DMAIC cycle of activity? a. develop, measure, apply, inspect, and control b. define, measure, assess, interpret, and correct c. define, measure, analyze, improve, and control d. describe, manage, assess, improve, and certify Answer: c Topic: Total Quality Management Page: 64 15. What is reverse engineering? a. disassembling and evaluating a competitor’s product b. obtaining product ideas from customers rather than from company engineers c. anticipating design flaws prior to the release of a product d. sending a product to a test market for review and then refining its design Answer: a Topic: Product Development Page: 66 16. If a product development cycle is well-managed, no portion of product ideas should fail. True or False? Answer: False Topic: Product Development Page: 66 17. What provides a structured format for bridging the gap between quality as conformance and quality as customer perception and expectation? a. ATO processing b. QFD analysis c. brainstorming d. fishbone diagrams Answer: b Topic: Product Development Page: 67 18. Which organization in the United States provides most of the responsibility for specifying minimum safety standards on products? a. The Consumer Product Safety Commission b. The Federal Trade Commission c. Congress d. The Small Business Administration Simpson and Hancock’s Practical Operations Management Chapter 3: Product Quality and Development Quiz Answer: b Topic: Product Development Page: 72 19. The ideal in product development is a ______ design, which involves planning sustainability as a perpetual cycle of transformation. a. cradle-to-gate b. cradle-to-grave c. cradle-to-cradle d. cradle-to-opportunity Answer: c Topic: Product Development Page: 73 20. Integration of a product’s design and process development phases to enhance manufacturability is referred to as ______ engineering. a. reverse b. simultaneous c. mass customization d. concurrent Answer: d Topic: Product Development Page: 74 21. The concept of manufacturability applies equally to both the production of goods and services. True or False? Answer: True Topic: Product Development Page: 74 22. If a company wants to meet individual customer needs, yet still employs the efficiency of highvolume production processing, its goal might be best characterized as ______. a. mass customization b. concurrent engineering c. continuous processing d. statistical process control Answer: a Topic: Product Development Page: 74 23. Which of the following consistently ranks at the top of the list of the most dangerous processes around the world? Simpson and Hancock’s Practical Operations Management Chapter 3: Product Quality and Development Quiz a. b. c. d. oil and gas production farming, logging, and fishing nuclear energy production chemical manufacturing Answer: b Topic: Product Development Page: 75 24. Maximizing safety and sustainability in production begins with ______. a. establishing clear objectives b. well thought-out designs c. proper employee training d. identifying and preventing risk Answer: d Topic: Product Development Page: 75 25. Proaction is the avoidance of preventable risk. True or False? Answer: True Topic: Product Development Page: 75